Safety and Workforce Overview

Performance Highlights

We are proud to play a role in maintaining U.S. energy security and to providing the reliable, affordable energy that the world needs. Being a safe, responsible operator with a team of the best and brightest people is critical to earning our license to operate and helps us create long-term value for shareholders.

We are defined by our corporate values: collaborate, take ownership, be bold and deliver results, and our team delivers on these values daily. We attract, develop and engage a diverse, empowered and talented workforce and work together as ‘One Team.’

2022 Safety Metrics

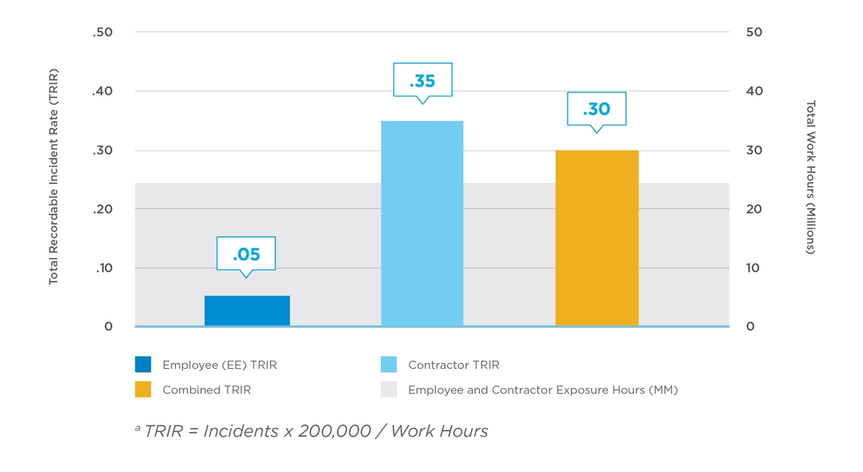

Given the intense increase in demand for reliable, low-cost energy in 2022, our employees and contractors worked 24 million hours, up from 16 million hours in 2021. Our total recordable incident rate (TRIR) is one of the metrics we use to measure our success in providing a safe working environment and is linked directly to compensation outcomes.

Despite the tumultuous economic, workforce and operational landscape in 2022, teams across the company gave their all to safety and we’re proud to have achieved our third-best year in company history for TRIR. Our combined TRIR for both employees and contractors was 0.30 in 2022 compared to 0.29 in 2021. Employees and contractors are expected to report all incidents, including “near misses.” In 2022, our near-miss frequency rate was approximately 6.39, a significant decrease from 9.09 in 2021.

- ᵃ TRIR = Incidents x 200,000 / Work Hours.

2022 In-Depth Global Safety Performanceᵃ

Safety Management

Safety Management

At Marathon Oil, safety is one of our core values, and we’re committed to providing workplaces where everyone can perform at their best, free of injury and illness.

Contractor Safety

Marathon Oil partners with top-rated contractors who share our commitment to safeguarding our workforce, communities, property and the environment.

HES Training

Our training program helps our workforce protect itself, our customers and the communities in which we operate.

How are we doing?

Your opinion matters. Please take a moment to let us know how useful you find the content on this page.

If you’d like to give us your feedback on the entire report, please fill out the complete survey for the 2022 report.